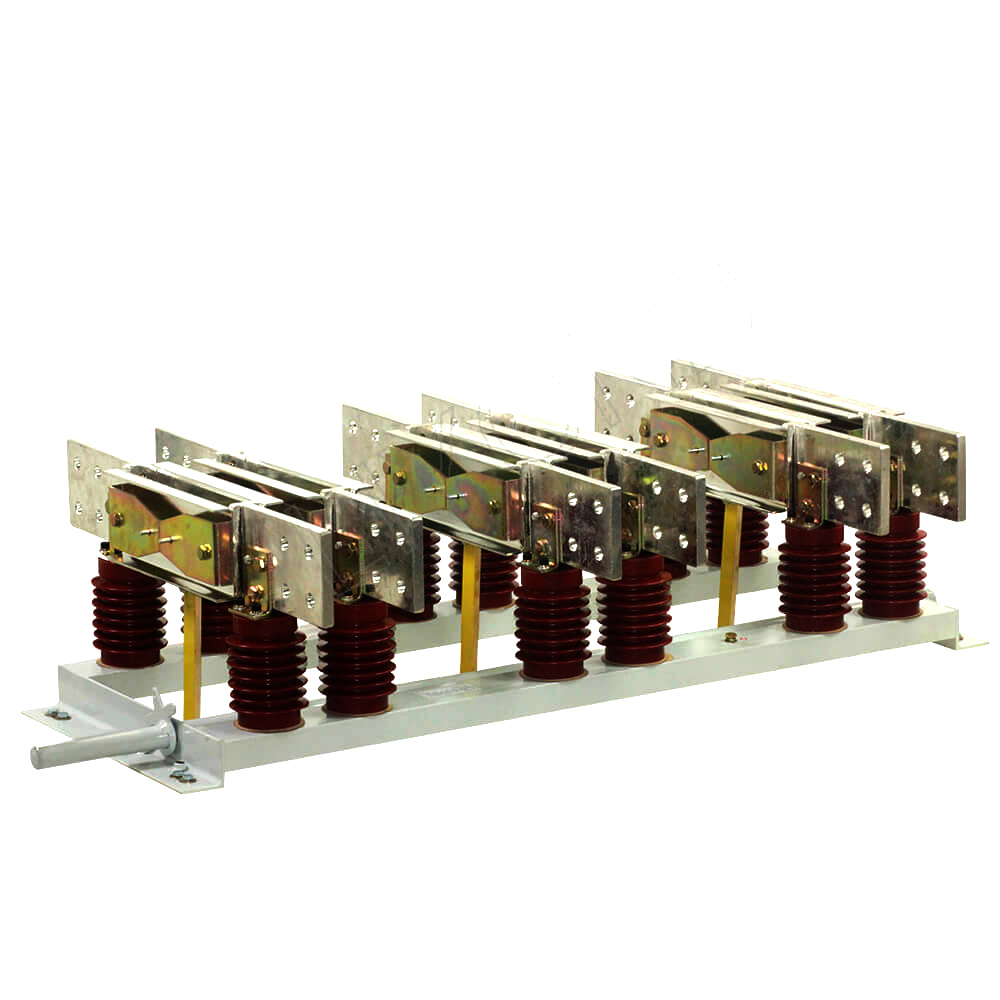

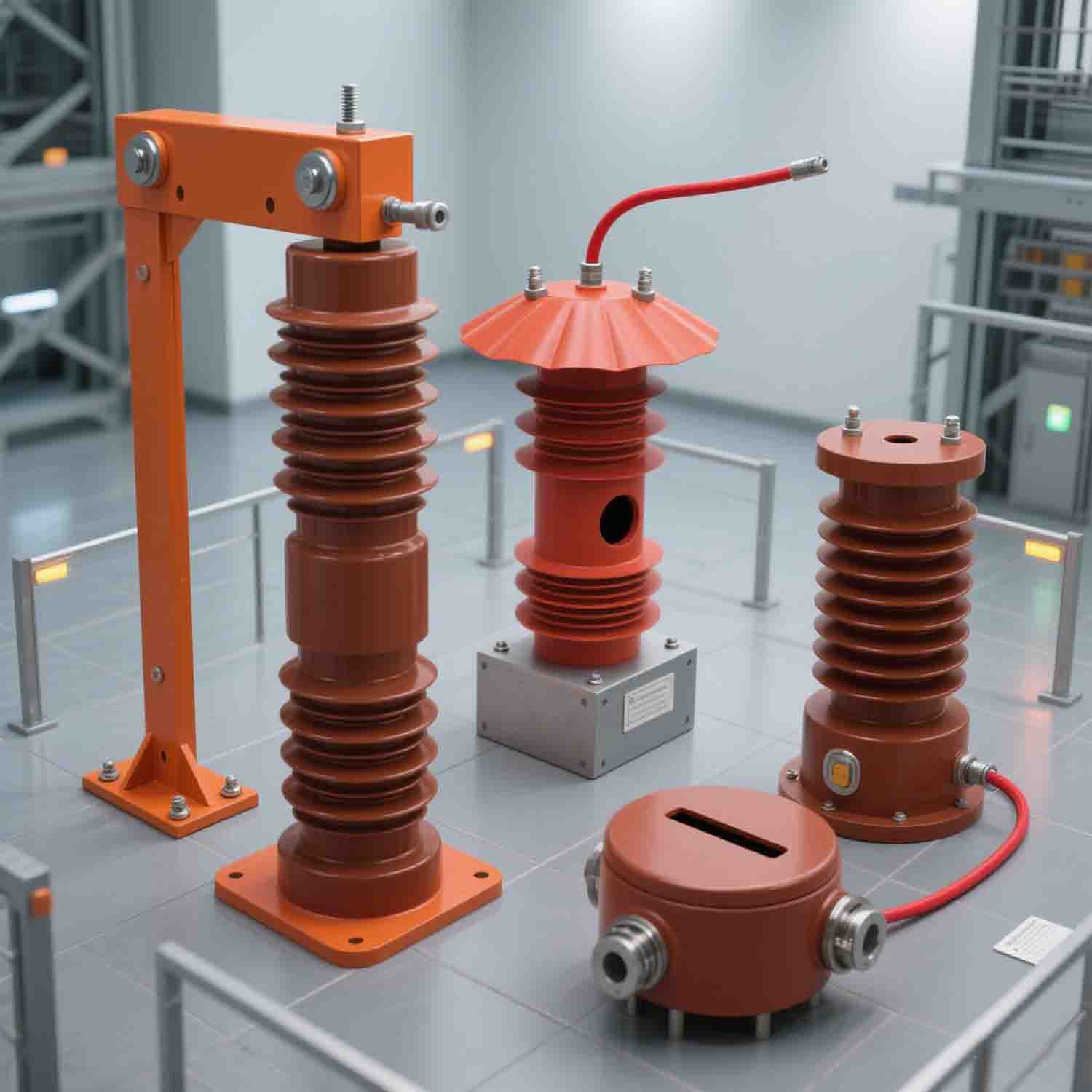

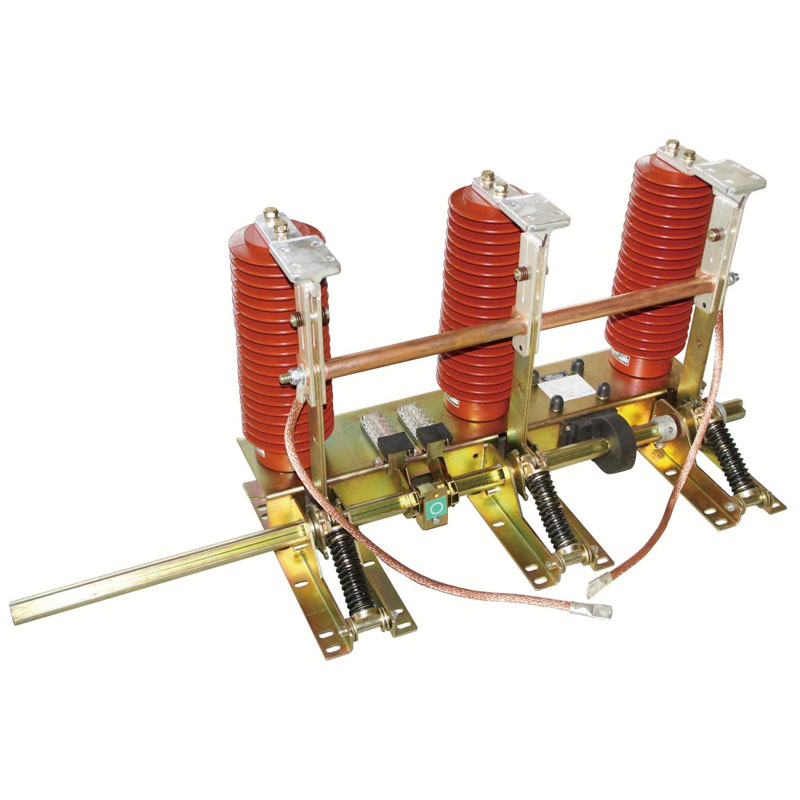

35kV high voltage insulation is a key component used to isolate charged parts, withstand electrical strength and support mechanical structures in 35kV voltage level power equipment.

35kV high voltage insulation is a key component used to isolate charged parts, withstand electrical strength and support mechanical structures in 35kV voltage level power equipment.

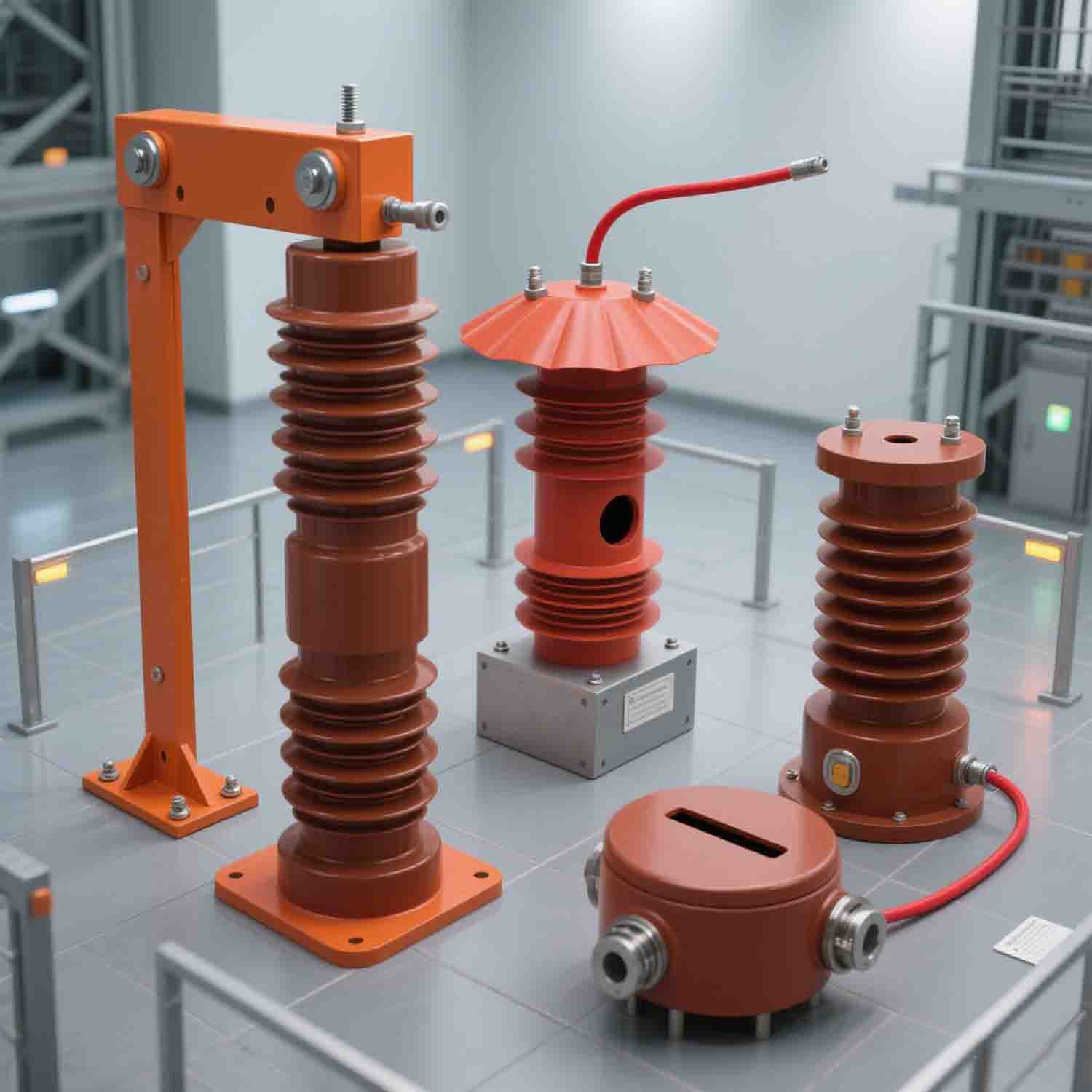

High-voltage insulation components must have high electrical strength (withstand 35kV voltage), good mechanical strength (support conductor or equipment weight), aging resistance (resistance to arc, heat, chemical corrosion) and environmental adaptability (moisture-proof, dust-proof, temperature difference-resistant)

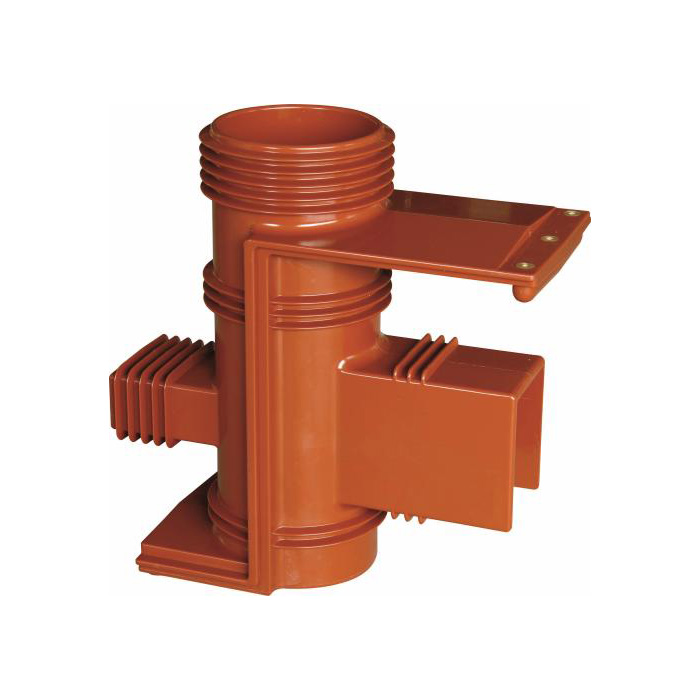

1. Features: excellent insulation performance, high mechanical strength, mature molding process (such as vacuum casting), chemical corrosion resistance, widely used in cast insulation parts.

2. Applications: insulators, bushings, contact boxes, insulating partitions, etc.

35kV high-voltage insulation components are the "safety barrier" of high-voltage power equipment. Their performance depends on material selection, manufacturing process and operation and maintenance level. In actual applications, it is necessary to select them reasonably according to the equipment type (such as switchgear, transformer, cable) and environmental conditions (indoor/outdoor, humidity, pollution level), and ensure insulation reliability through regular inspection and maintenance to prevent power outages or safety hazards caused by insulation failure.

35kV high voltage insulation is a key component used to isolate charged parts, withstand electrical strength and support mechanical structures in 35kV voltage level power equipment.

35kV high voltage insulation is a key component used to isolate charged parts, withstand electrical strength and support mechanical structures in 35kV voltage level power equipment.